Sweeping machine: features, functions and use

Learn about the features, functions and types of professional sweepers. Read MP-HT's advice for an informed and safe choice.

Read the article

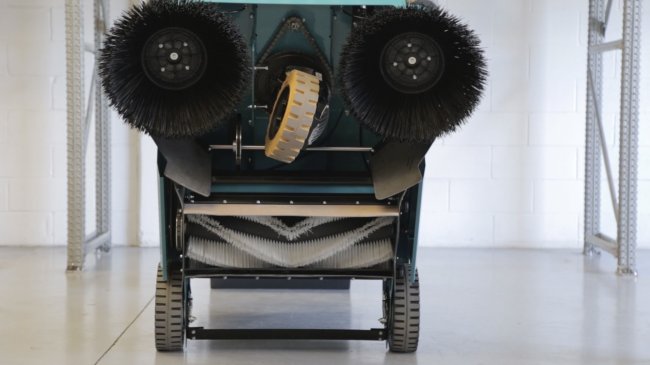

Aware of the importance of keeping the brushes clean and free, the MP-HT technical department has put some small features in the design and construction of its sweepers, to facilitate inspection on the one hand and to simplify and reduce the maintenance requirement on the other.

MP-HT sweepers have a structural conformation that allows one to inspect the main components of the machine with the utmost ease, including the brushes: just remove or raise the waste container and in the blink of an eye the operator is able to check the possible presence of jammed material and the condition of the central brush.

Another choice, standard on some models such as the WIND ZERO and optional on others such as the AGILE ride-on or the HANDY walk-behind, is the side brush with electric gear motor, without belts. In addition to better withstanding the shocks caused by work, the main advantage of electric brushes is a lower maintenance requirement, a substantial reduction in the time required for any repairs compared to brushes with belt drives and therefore a reduction in costs.

For over thirty years we have been producing industrial sweepers and urban sweepers capable of making cleaning not an obstacle to be overcome (which hinders work) but a practice capable of adding value to one’s work, useful for saving time and money.

Discover all the benefits of MP-HT sweepers, and how they will help you transform the cleaning task from an expensive hassle into an added value for your company.

Sweeping the ground is a clean-up operation that practically all of us have done. Regardless of whether the activity is manual or mechanical, the type and quality of the brush, whether it is that installed in a professional sweeper or that of a simple broom, has a fundamental influence on the effectiveness and the sweeping results that can be obtained.

The side and central brushes are key parts of the sweeper.

The sweeping system consists of one or more side brushes, which convey the dirt towards the centre, i.e., towards the central, roller brush, which has the task of loading the dirt into the waste container.

In front-loading sweepers, the central brush moves the dirt forward, while in rear-load sweepers it “throws” it back towards the container located at the rear of the machine.

Understanding and knowing how to choose the most suitable type of brush for the type of dirt and surface to be cleaned has a significant impact on the cleaning performance of the machine, just as careful maintenance guarantees effective work over time.

In sweepers, therefore, there are two main types of brushes:

When choosing the brush, in addition to examining its technical characteristics, it is important to evaluate the type of flooring and dirt to be cleaned.

Indicatively, to collect coarse and heavy dirt, even adhering to the floor (e.g., damp leaves), it is recommended to install brushes whose bristles are stiffer, suitable for collecting heavy and coarse dirt (e.g., metal materials and powders in workshops and carpentry shops), while softer and thinner bristles are more suitable for collecting light and very fine dirt.

If there is a need to scrape the surface on the ground, it is advisable to install brushes with polypropylene bristles together with steel bristles.

For a good cleaning job, another fundamental aspect is regular and careful maintenance of the brushes. There are a few simple precautions to take into consideration to ensure that the brushes, central and lateral, remain efficient over time: